The NBS Smoke Density Chamber is considered to be one of the most widely used test equipment for the measurement of the smoke generated from the burning material, such as building material, non-metallic material in railway, marine, and the airplane.

The NBS Smoke Density Test is intended primarily for use in research and development and fire safety engineering in buildings, trains, ships, etc., and not as a basis for ratings for building codes or other purposes. No basis is provided for predicting the density of smoke that might be generated by the materials upon exposure to heat and flame under other (actual) exposure conditions.

The following data can be reported by the smoke density test:

Specific optical density, Dsmax, Ds10, Ds1.5, Ds4.0.

Clear-beam correction factor Dc.

VOF4.

Results derived from different standards.

ASTM E662 Test Furnace

NBS Smoke Density Chamber Training

NBS Smoke Density Chamber consists of

Thick stainless steel made test chamber, with the inner size of 914mm by 914mm by 610mm.

The inner surface of NBS chamber is coated with Teflon, which resists chemical attack and corrosion and is easy to cleanse.

Full opening door allows easy access for sample loading and chamber cleansing.

The door with an observation window and a removed opaque door cover to the window to prevent light entering into the chamber.

Chamber walls are pre-heated for easier start-up and convenient equipment operation.

A safety device to prevent explosion, easily replaceable, allows for the safe operation of the test method.

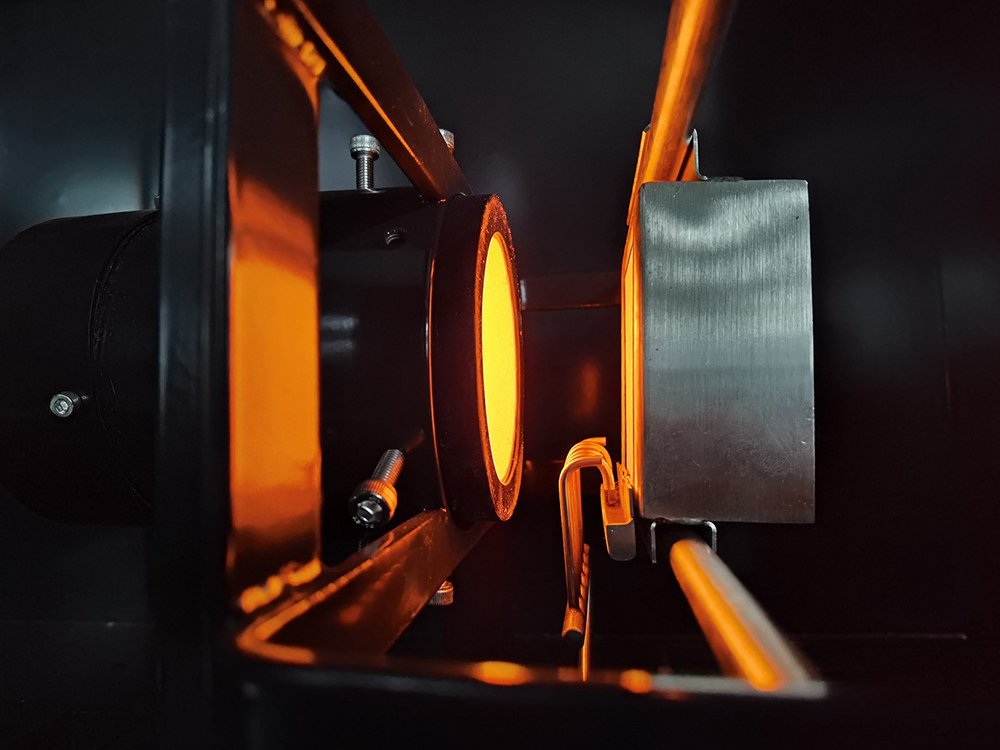

Two optical windows, each with a diameter of 75mm, are mounted in the top and bottom of the chamber.

The light measuring system consists of an incandescent lamp and a photomultiplier tube.

Provided with a range-extension filter in the light path, adjusting the accuracy of the instrument under any scale.

ISO 5659-2 Conical heater, rates 2600 W at 230 V with a heat output up to 50 kW/m2.

Auto split shutter automatically opened to transmit radiation to the sample, auto ignited the pilot flame.

Heat flux meter, uses for setting the irradiance level at the surface of the specimens, the range from 0-100kW/m2.

ASTM E662 Furnace heater for vertical mounted, rates 550W at 110 V with a heat output up to 25 kW/m2.

The movement of the sample is controlled by the air cylinder automatically.

No pilot flame and pilot flame modes are provided. The digital display flow rate of air and propane.

Gas measurement ports are provided, for optional measurements of toxic gases.

19” analysis rack, 15” touch screen panel type PC for the whole control, and automatic testing.

DAQ (Data Acquisition) program controllable with the touch screen panel PC.

Advanced Options

FTIR Toxicity test system.