FAR 25.853 Fire Test for Aviation Materials

How FAR 25.853 Created?

In the past, fire safety and related testing requirements in the cabin were not the first consideration in the aviation industry, what mattered most was the convenience of the passengers.

The first regulations applicable to fire safety on aircraft were issued between the 1940s and 1960s and applied to passenger aircraft with 50-150 seats. Fire testing of materials was also limited to the vertical flame spread test, and the aviation industry also recommended more comprehensive testing methods to improve the safety of cabin materials.

In 1983, an Air Canada DC-9 aircraft flying from Dallas to Toronto was flying at 33,000 feet when smoke emerged from the washroom and flames quickly spread to the cabin walls and to more flammable items, such as plastic parts and seats.

The plane even jumped into flames after an emergency landing due to the availability of fresh oxygen. The accident ultimately resulted in the death of 23 of the 46 passengers.

Subsequently, the Federal Aviation Administration (FAA) updated its requirements regarding the fire safety of aircraft materials, and after 1988 more interior materials on aircraft had to be tested for fire safety, and adjusted the applicable plane to 20 seats or more.

Aircraft cabins are made from a large number of lightweight polymers or composites and because they fly at high altitudes, making the possibility of escape in the event of a fire limited, an aircraft fire poses a significant risk to the lives of passengers and crew. There is therefore a need to ensure that the materials used in the cabin should have limited flammability, smoke production properties, and increased fire resistance through structural design to limit the spread of flames and improve the safety of personnel.

To today, most countries have adopted the US Federal Regulations (FAR), or have issued equivalent domestic regulations, to require the fire safety of materials and composites used in aircraft construction.

In USA

The regulations are published by the Federal Aviation Administration (FAA). The associated document is called FAR 25.853 (Federal Aviation Regulation).

In Europe

The regulations are published by EASA (European Aviation Safety Agency), the equivalent document is called CS 25.853 (Certification Specification), or JAR 25.853.

In China

The regulations are published by CAAC (Civil Aviation Administration of China), the equivalent of CCAR 25.853.

The FAR, CS, JAR, and CCAR are essentially identical in content, in that both regulations set out the code for large commercial aircraft in section 25 and the reaction to fire performance of aircraft interior materials in paragraph 853. Therefore, the regulations described in FAR 25.853, CS 25.853, JAR 25.853, and CCAR 25.853 are similar and may even be said to be the same.

In addition, Airbus and Boeing also have internal test methods for determining the fire safety of cabin materials. The Airbus is AITM (Airbus Industrial Test Method), also called ADB 0031. The Boeing is BSS (Boeing Safety Standard). They are all highly consistent with FAR 25.853 test methods, and additional requirements for more materials to be smoke tested, and requirements for toxicity testing of materials.

Fire Test Regulation for Aircraft Materials

FAR 25.853 (CS 25.853, JAR 25.853, CCAR 25.853)

Part I Test Criteria and Procedures for Showing Compliance with Sec. 25.853, or 25.855.

Part II Flammability of Seat Cushions.

Part III Test Method to Determine Flame Penetration Resistance of Cargo Compartment Liners.

Part IV Test Method to Determine the Heat Release Rate From Cabin Materials Exposed to Radiant Heat.

Part V Test Method to Determine the Smoke Emission Characteristics of Cabin Materials.

Part VI Test Method To Determine the Flammability and Flame Propagation Characteristics of Thermal/Acoustic Insulation Materials.

Part VII Test Method To Determine the Burn through Resistance of Thermal/Acoustic Insulation Materials.

Airbus Industrial Test Method (AITM / ABD0031)

AITM 2.0002 Vertical Burn

AITM 2.0003 Horizontal Burn

AITM 2.0004 45 Degree Burn

AITM 2.0005 60 Degree Burn

AITM 2.0006 Rate of Heat Release (OSU)

AITM 2.0007 Smoke Density

AITM 2.0008 Smoke Density for Insulted Wire / Cable

AITM 2.0009 Oil Burner Seat Cushion Fire Blocking

AITM 2.0010 Oil Burner Cargo Liner

AITM 2.0053 Insulation (Flame Propagation)

AITM 2.0056 Insulation (Burnthrough)

AITM 3.0005 Combustion Toxicity

Boeing Safety Standard (BSS)

BSS 7230 F1 Vertical Burn (60 second)

BSS 7230 F2 Vertical Burn (12 Second)

BSS 7230 F3 Horizontal Burn (2.5”)

BSS 7230 F4 Horizontal Burn (4.0”)

BSS 7230 F5 45 Degree Burn

BSS 7230 F6 60 Degree Burn

BSS 7238 Smoke Density

BSS 7239 Combustion Toxicity

BSS 7303 Oil Burner Seat Cushion Fire Blocking

BSS 7322 Rate of Heat Release

BSS 7323 Oil Burner Cargo Liner

BSS 7365 Insulation (Flame Propagation)

BSS 7387 Insulation (Burnthrough)

Aircraft Materials Fire Test Handbook

The FAA published Aircraft Materials Fire Test Handbook (latest version, DOT/FAA/AR-00/12).

The purpose of the Aircraft Materials Fire Test Manual is to describe all FAA-required aircraft materials fire test methods in a consistent and detailed description, and the information provided in the handbook enables the user to conduct the test methods correctly. Moreover, it supplements additional test methods that are not specified in the FAR regulations for the user's reference. Also included in the appendices is a wealth of information on FAA fire tests, such as FAA regulation explanation, regulation approval procedures, materials used in testing, methods, instrument suppliers, etc.

The FAA accepts the test methods described in Chapters 1 to 10 of the Handbook as providing an equivalent level of safety to the test methods specified in Appendix F of part 25. And these test methods in the handbook are more repeatable, more reproducible, and easier to conduct.

Chapter 1 Vertical Bunsen Burner Test for Cabin and Cargo Compartment Materials

Chapter 2 45-Degree Bunsen Burner Test for Cargo Compartment Liners and Waste Stowage Compartment Materials

Chapter 3 Horizontal Bunsen Burner Test for Cabin, Cargo Compartment, and Miscellaneous Materials

Chapter 4 60-Degree Bunsen Burner Test for Electric Wire

Chapter 5 Heat Release Rate Test for Cabin Materials

Chapter 6 Smoke Test for Cabin Materials

Chapter 7 Oil Burner Test for Seat Cushions

Chapter 8 Oil Burner Test for Cargo Liners

Chapter 9 Radiant Heat Test for Evacuation Slides, Ramps, and Rafts specified in Technical Standard Order (TSO)-C69C (“Emergency Evacuation Slides, Ramps, Ramp/Slides, and Slide/Rafts”).

Chapter 10 Fire Containment Test of Waste Stowage Compartments

Table of Aircraft Material Fire Test Methods

| FAR 25.853 | Fire Test Handbook | Airbus AITM | Boeing BSS | Method | Equipment |

|---|---|---|---|---|---|

| Part I (a)(1)(ii) | Chapter 1 | AITM 2.0002A | BSS 7230: F1 | Vertical Flammabilty (60s) | Flammability Chamber |

| Part I (a)(1)(i) | Chapter 1 | AITM 2.0002B | BSS 7230: F2 | Vertical Flammability (12s) | Flammability Chamber |

| Part I (a)(2)(iii) | Chapter 2 | AITM 2.0004 | BSS 7230: F5 | 45 Degree Flammability | Flammability Chamber |

| Part I (a)(3) | Chapter 4 | AITM 2.0005 | BSS 7230: F6 | 60 Degree Flammability | Flammability Chamber |

| Part I (a)(iv)&(v) | Chapter 3 | AITM 2.0003 | BSS 7230: F3&F4 |

2.5" Horizontal Flammability 4.0" Horizontal Flammability |

Flammability Chamber |

| Part IV | Chapter 5 | AITM 2.0006 | BSS 7322 | Rate of Heat Release | OSU Rate of Heat Release |

| Part V | Chapter 6 | AITM 2.0007 | BSS 7238 | Smoke Density | NBS Smoke Density Chamber |

| Part II | Chapter 7 | AITM 2.0009 | BSS 7303 | Oil Burner Seat Cushion | FAA Oil Burner for Seat Cushion |

| Part III | Chapter 8 | AITM 2.00010 | BSS 7323 | Oil Burner Cargo Liner | Oil Burner for Cargo Liner |

| Part VI | N.A. | AITM 2.00053 | BSS 7365 | Insulation (Flame Propagation) | Thermal or Acoustic Insulation Flame Propagation Apparatus | Part VII | N.A. | AITM 2.00056 | BSS 7387 | Insulation (Burnthrough) | FAA Oil Burner for Insulation Burn Through Resistance | N.A. | Chapter 12 | N.A. | N.A. | Power Plant Oil Burner Fire Penetration | FAA Oil Burner for Powerplant Fire Penetration | N.A. | Chapter 18 | N.A. | N.A. | Blanket Flammability | Flmmability Chamber | N.A. | N.A. | AITM 3.0005 | BSS 7239 | Gas Toxicity | Toxic Chamber |

Test Methods Introduction

Generally use the F.I.R.S.T. principle to assess the fire performance of materials in the building & railway industries, where “F” stands for Flame Spread, “I” stands for Ignitability, “R” stands for Rate of Heat Release, “S” stands for Smoke Density, and “T” stands for Toxicity.

The F.I.R.S.T principle also works to assess the fire performance of aircraft materials, where these are:

Ignitability (Flammability)

Vertical Flammability (12s & 60s)

Vertical Flammability

45 Degree Flammability

60 Degree Flammability

Horizontal Flammability (2.5” &4.0”)

Blanket Flammability

Heat Release

Rate of Heat Release (OSU)

Smoke Density

Smoke Density (NBS)

Flame Spread

Oil Burner for Seat Cushion

Oil Burner for Cargo Liner

Oil BUrner for Insulation Burnthrough

Oil burner for Powerplant Fire Penetration

Insulation Flame Propagation

Toxicity

Gas Toxicity ( AITM 3.0005 & BSS 7239)

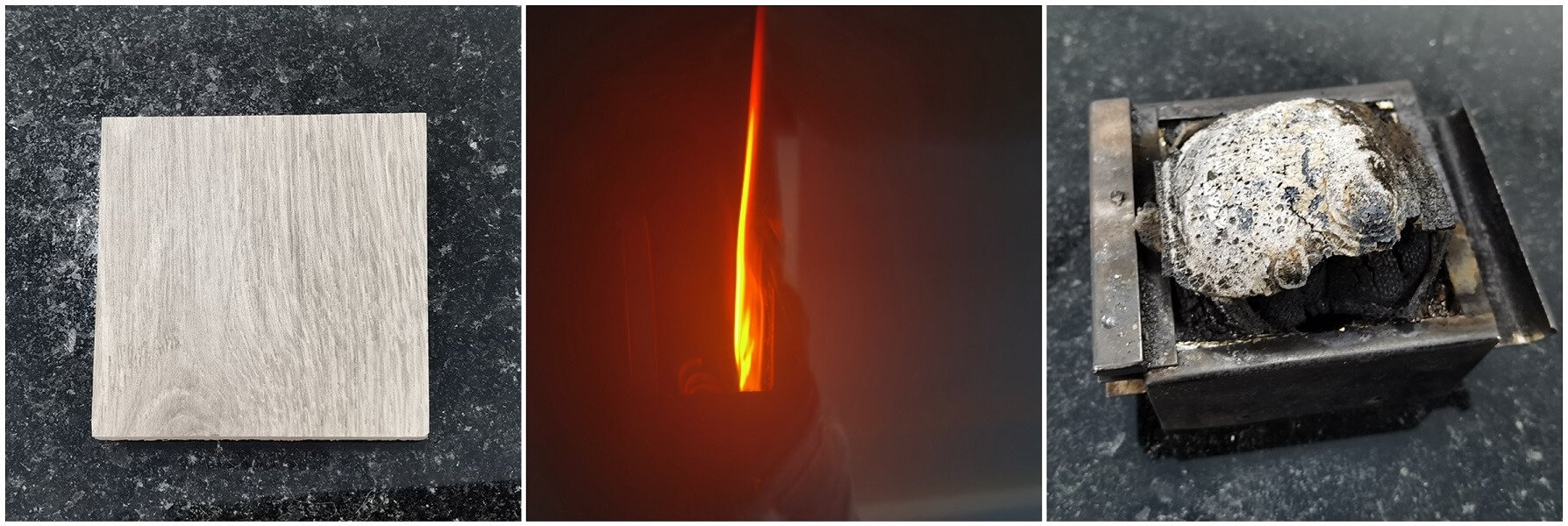

Flammability Test

Introduction

Determine the flammability of the material exposed to a bunsen burner flame.

10 mm Inside diameter Bunsen burner.

Methane gas (99% min. purity) fueled.

38mm, 76mm Flame height in vertical mounted.

Burner orientation: 90°, 45°, 30°,

Implement time: 12s or 60s in the vertical test;

30s in the 45 degree test;

15s in the horizontal test;

30s in 60 degree test;

12s in the blanket test.

Application

Cabin & cargo compartment materials.

Cargo Compartment Liners & Waste Stowage Compartment Materials.

Cabin, Cargo Compartment, & Miscellaneous Materials.

Electric Wire

Aircraft Blankets

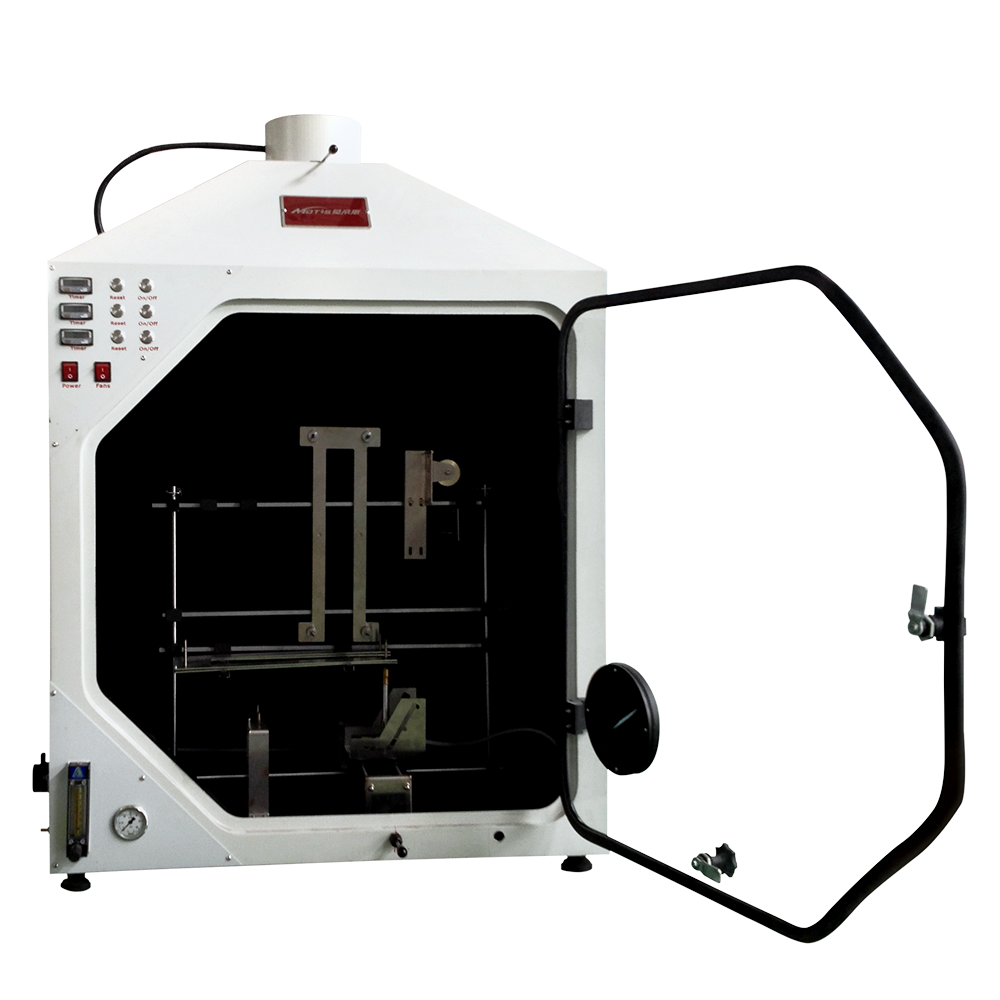

MOTIS’s Flammability Chamber

Meets all flammability tests of FAR 25.853, AITM, BSS, and Aircraft Material Fire Test Handbook tests.

Standard Bunsen burner.

Movable Bunsen burner with angle adjustment.

Multiple specimen holders with fixture tools.

Rate of Heat Release Test

Introduction

Determine the heat release rate of burning aircraft cabin material when exposed to a radiant heat source with a constant airflow pass.

Convective heat principle.

3.5 W/cm2 radiant heat source.

0.04 m3/s Constant airflow in the temperature of 21 to 24d°C for combustion.

Thermopiles for heat release measurement.

Application

Cabin materials.

MOTIS’s OSU Rate of Heat Release Apparatus

Meets all rate of heat release tests of FAR 25.853, AITM, BSS, and Aircraft Material Fire Test Handbook, ASTM E906 tests.

Stainless steel test chamber with wall insulation inside.

Silicon carbide heating elements with dual power supply, providing a constant 3.5 W/cm2 radiant heat source.

Self-contained air distribution system for test, includes an adjustable blower, airflow cooling system, heating exchange device, and airflow measurement device.

Multiple calibrated flow meters.

Automated system calibration procedure.

Smoke Density Test

Introduction

Determine the smoke generating density of cabin interior materials when exposed to a 2.5 W/cm2 radiant heat source in a closed chamber.

Closed test chamber with an internal volume of 0.51 m3.

Vertical mounted radiant heat furnace with an output of 2.5 W/m2.

Vertically mounted specimen.

Non-flame & flame application tests.

Incandescent lamp photometric system for smoke density measurement.

Application

Cabin materials.

MOTIS’s NBS Smoke Density Chamber

Meets all smoke density tests of FAR 25.853, AITM, BSS, and Aircraft Material Fire Test Handbook, ASTM E662 tests, can be extended to ISO 5659-2 test.

SS 316 Test chamber with Teflon coating for anti-corrosion.

White light smoke photometric system.

Stainless steel specimen holder with auto feeding stand.

Can be connected toxicity chamber.

Easy to use software.

Oil Burner Test

Introduction

Evaluate the flammability, burn resistance, and flame spread of aircraft components when exposed to a high-intensity open flame.

Hign-intensity open flame implement.

Multiple flame implement directions for different products.

Application

Seat cushion.

Cargo liner.

Insulation.

Powerplant

MOTIS’s Oil Burner System

Meets all oil burner tests of FAR 25.853, AITM, BSS, and Aircraft Material Fire Test Handbook tests.

Full automatic test system, includes an oil burner, specimen feeding device, calibration device, and remote control software.

Standard oil burner recommended in FAR 25.853.

Flexible combination of individual tests or multiple tests.

Specimen holder with automatic feeding device, release labor work intensity and improve the test repeatability.

Remote control software, improves test safety.

Propagation Test

Introduction

Evaluate the flammability & flame propagation characteristics of thermal/acoustic insulation when exposed to both a radiant heat source and a flame.

Electric radiant heat source with a radiant output of approx. 1.7 W/cm2.

The specimen is horizontally mounted and the radiant panel is mounted above the specimen at 30°.

Record the flame propagation distance, after flame time during the test.

Application

Thermal & Acoustic Insulation Materials

MOTIS’s Thermal / Acoustic Insulation Flame Propagation Apparatus

Meets all insulation propagation tests of FAR 25.853, AITM, and BSS tests.

Stainless steel test chamber with wall insulation inside.

Standard recommended electric radiant heat panel.

Automated specimen feed-in.

Automated pilot flame applicaiton.

Easy to use software.

Toxicity Test

Introduction

Determine the toxic gas generating characteristics of the burning aircraft material connecting the NBS smoke density chamber.

Extract toxic gas from the NBS chamber.

Analyze toxic gases including CO, CO2, HCN, NOx, SO2.

Colorimetric gas detector tube measurement.

Application

Aircraft materials.

MOTIS’s Toxicity Chamber

Quick connect to the Smoke Density Chamber.

Colorimetric gas detector tube measurement.

Summary

FAR 25.253 is a standard of the Federal Aviation Administration (FAA) for determining the flammability characteristics of materials & components used in the aircraft.

The purpose is to establish repeatable, reproducible, easy test methods to assess potential fire risks that may be happened in the aircraft. The test methods are assessed in terms of flammability, heat release, smoke density, flame spread, and toxicity.

FAR 25.853 has become the guideline for fire safety tests in the aviation industry and has been accepted by many countries and aircraft manufacturers and has developed regulations and test standards in relation to it.