Smoke Density Test: ISO 5659 VS ASTM E662

Smoke Density Test Methods

The NBS smoke density chamber is widely used in the smoke generation characteristics research of plastics, construction materials, railway materials, aviation materials, marine materials, etc. There are different test standards and test models for different fields or countries.

| Area | Standard |

|---|---|

| International |

ISO 5659-2 |

| Unite State |

ASTM E662, ASTM F814, NFPA 258 |

| United Kingdom |

BS 6401, NES 711 |

| China |

GB/T 8323.2 |

| Japan |

JIS K 7242-2 |

| International Maritime Organization |

FTP CODE 2010 PART 2 |

Categories

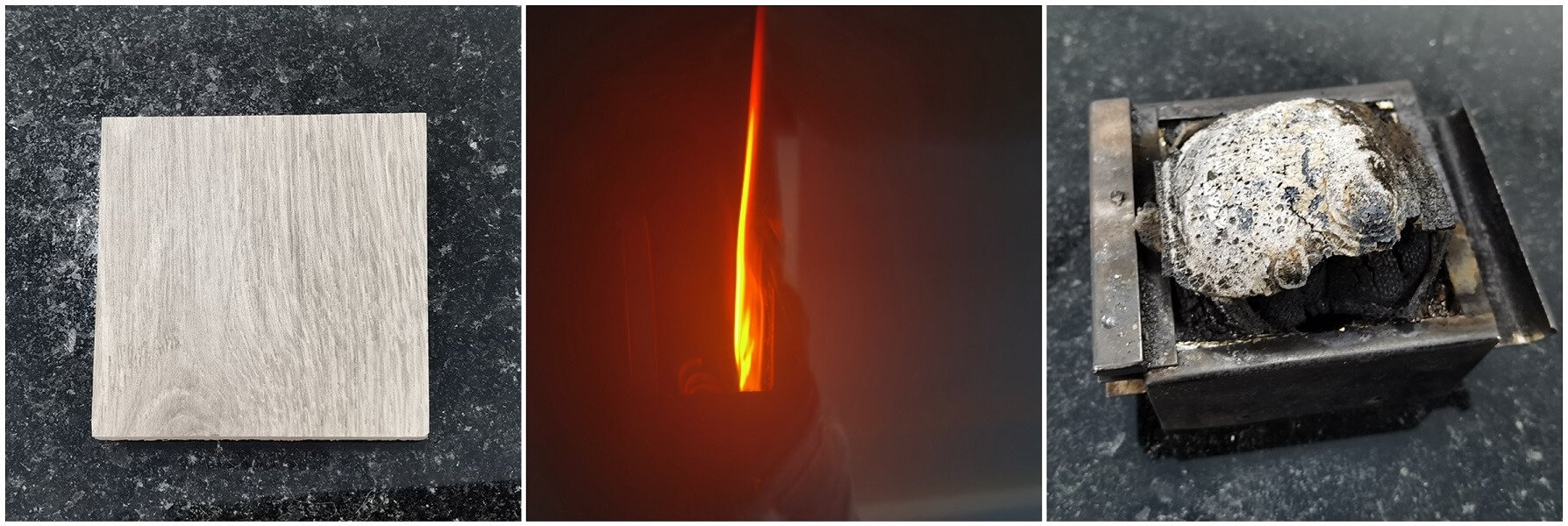

Depending on the radiant heat source, it can be categorized into two groups, horizontal radiant cone and vertical radiant furnace.

| Horizontal Radiant Cone | Vertical Radiant Furnace |

|---|---|

|

ISO 5659-2

GB/T 8323.2

JIS K7242-2

FTP CODE 2010 |

ASTM E662

ASTM F814

NFPA 258

BS 6401

NES 711 |

ISO 5659-2 VS ASTM E662

Of all the standards, ISO 5659 and ASTM E662 are the most widely used. Below is a comparison of the similarities and differences between ISO 5659 and ASTM E662.

| Items | ISO 5659-2 | ASTM E662 |

|---|---|---|

|

Radiant Source |

Horizontal Radiant Cone |

Vertical Radiant Furnace |

|

Power Rate |

2600W |

525W |

|

Radiant Orientation |

Horizontal |

Vertical |

|

Heater |

Cone-shaped radiator with a radiant opening of φ 110mm. |

Cylindrical radiator with a radiant opening of φ 76.2mm. |

|

Radiant Rate |

0-50 kw/m2 |

25 kw/m2 |

|

Heat Flux Meter |

Water-cooled, Schmidt-Boelter type,with a φ 10mm receiving face. |

Air-cooled, Gardon type. with a φ 38mm receiving face. Note:φ 25mm Schmidt-Boelter type heat flux meter is optional. |

|

Specimen |

75mm x 75mm, thickness less than 25mm. |

76.2mm x 76.2mm, thickness less than 25.4mm. |

|

Specimen Conditioning |

Shall be conditioned to constant mass at 23 °C ± 2 °C and a relative humidity of (50 ± 10) % |

Pre-dry specimens for 24 h at (60±3°C) and then condition to constant mass at 23 °C ± 3 °C and a relative humidity of (50 ± 5) % |

|

Exposed Area |

65mm x 65 mm |

65.1 x65.1 mm |

|

Exposed Distance |

Horizontal, 25mm |

Vertical, 38mm |

|

Pilot Burner |

Single-flame burner |

Six-tube burner |

|

Burner Fueled |

Propane & Air mixed with a flow of 50mL/min Propane & 300mL/min Air |

Propane & Air mixed, with a flow of 50mL/min Propane & 500mL/min Air |

|

Pilot Flame |

30mm long, 10mm above the specimen surface |

Isometric small flame 6.4mm away from the face of the specimen |

|

Test Duration |

10min |

20min |

|

Test Mode |

Irradiance 25 kW/m2, no pilot flame;

Irradiance 25 kW/m2, pilot flame;

Irradiance 50 kW/m2, no pilot flame;

Irradiance 50 kW/m2, pilot flame. |

Irradiance 25 kW/m2, no pilot flame;

Irradiance 25 kW/m2, pilot flame; |

|

Weight Measurement |

Optional |

No |

Summary

Both ISO 5659 and ASTM E662 are used to measure the loss of luminous flux due to the reflection of light by solid dust in the smoke produced by burning materials to evaluate the smoke density. The principle of the test is based on the Beer-Lambert law, where a monochromatic beam of light is shone on the surface of an absorbing medium, and after passing through a certain thickness of the medium, the intensity of the transmitted light is reduced as the medium absorbs some of the light energy. Both test methods use the same test chamber and photometric system.

The most obvious difference between the two is that ISO 5659 uses a horizontally placed radiant heat cone while ASTM E662 uses a vertically placed radiant heat furnace.

Lastly, test results are not comparative.

Contact us to learn more about the smoke density tests and instruments.

Email: sales@motistech.com